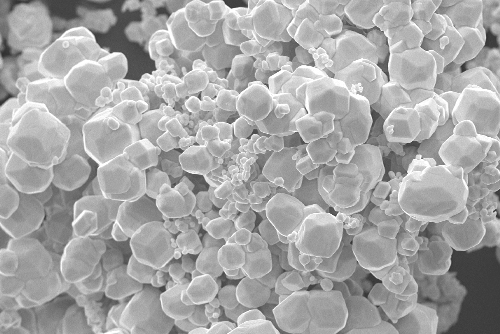

Tungsten metal from

Not only does tungsten have the highest melting point (3,422 °C) and the lowest thermal expansion of any metal, it also has a high density (19.3 g/cm³), very high mechanical stiffness, and a very low vapor pressure. Thanks to these and other outstanding properties, tungsten metal is irreplaceable in many key industries.

Characteristics of tungsten metal

Tungsten heavy metal alloys exploit the metal’s high density, mechanical damping properties, high absorption capacity for ionising radiation, and easy machining characteristics. These alloys are used as mass-balance weights and damping elements in aircraft construction, in engines and power units, and as flywheel masses and centrifugal weights in machinery and equipment construction. They are also used in medical technology to shield and focus ionising radiation in X-ray and measuring equipment. High thermal resistance and excellent thermal and good electrical conductivity make tungsten-copper alloys suitable for applications in high-performance electrical switching contacts, such as heat sinks in the electrical industry, or for use as discharge electrodes. What’s more, pure tungsten metal is also used in the coating industry as a crucible material and a sputter target, as well as in high-temperature furnaces in the form of heating elements and heat shields. H.C. Starck Tungsten Powders manufactures tungsten metal powders through the reduction of tungsten oxides under an atmosphere of hydrogen.

Applications for tungsten metal

Heavy metal alloys (W-Ni-Fe, W-Ni-Cu)

- Counterweights and anti-vibration parts, e.g. in airplanes and rotors

- X-ray and radiation shielding

Semi-finished products

- Filaments

- Electrodes

- Contact material (W-Cu)

Superalloy

- Alloy elements in superalloys

- Sputter targets

Oil and gas exploration

- Tungsten powder for the shoulder section of drill bits

- Shaped charges

starck2print®

Exceptionally good processing in additive manufacturing thanks to high purity: this is what our starck2print® tungsten powders offer you.

A wide range of products

We offer a wide range of different powder types with average FSSS grain sizes of approx. 0.4 µm to >50 µm. We would be happy to advise you on selecting the right powder for your specific application and on any questions regarding process optimisation. We are also happy to provide application-related support.

| Tungsten metal powder HC | conventional tungsten metal powders with high level of purity and a wide range of available grain sizes |

| Tungsten metal powder HC S | deagglomerated tungsten metal powders with very narrow grain size distribution |

| Tungsten metal powder D | slightly agglomerated tungsten metal powder with excellent cold pressing properties |

| Tungsten metal powder GG | special, coarse tungsten metal powders with very low oxygen content and excellent infiltration properties |

| Tungsten metal powder HC 4000 | coarse standard tungsten metal powder |

Assured quality and raw material supply

H.C. Starck Tungsten Powders has been manufacturing tungsten for one hundred years. Modern plants and processes on the one hand and competent employees on the other guarantee products of consistently high quality. Accredited analysis naturally guarantees that our products are manufactured in accordance with specifications. To ensure a sustainable and secure supply of raw materials H.C. Starck Tungsten Powders relies primarily on residual materials containing tungsten, which we recycle to produce ammonium paratungstate for the production of new tungsten metal powder. Our customers can also make use of tungsten product recycling as a service. We can rework almost all industrial residual materials or components containing tungsten into new, high-quality tungsten metal powder. In addition to recycled materials, we also have access to primary materials via our owner Masan High-Tech Materials. Masan High-Tech Materials has the largest tungsten deposits outside of China at its command.

Technical application support over the entire process chain

You can count on us to support you in the development and optimisation of materials, products, and processes, as well as in application technology. Our application engineers play a central role in the process, thanks to their expertise with materials, their decades of experience, their comprehensive understanding of metallurgical and chemical processes, and their knowledge of innovative fields involving markets, applications, and technologies. This enables them to work with you to develop initial ideas into practicable solutions.

Your contact partner for North America

Rob Scott

Tel. +1 (519) 346–4300–4362

rob.scott@hcstarck.com

Download product data sheets

Tungsten metal – downloads

Download the product data sheets for our tungsten metal powder directly here or visit our download area.