H.C. Starck Tungsten Powders is a world leader in the recycling of materials containing tungsten. Thanks to decades of experience, we are able to extract pure tungsten from almost all forms of tungsten scrap and production waste. The quality of the reclaimed raw material is absolutely identical to that of the primary material, and in some cases even better. What’s more, recycling enables us to reduce CO2 emissions and guarantee our customers security of supply.

Because competition for raw materials is fierce, the technically demanding recycling at H.C. Starck Tungsten Powders has become increasingly important as an indispensable strategic element of a stable raw material supply, supplementing access to primary raw materials via our owner Masan High-Tech Materials. It makes us independent of raw material availability, which benefits our customers as well. In this way, ecological and economic advantages are combined.

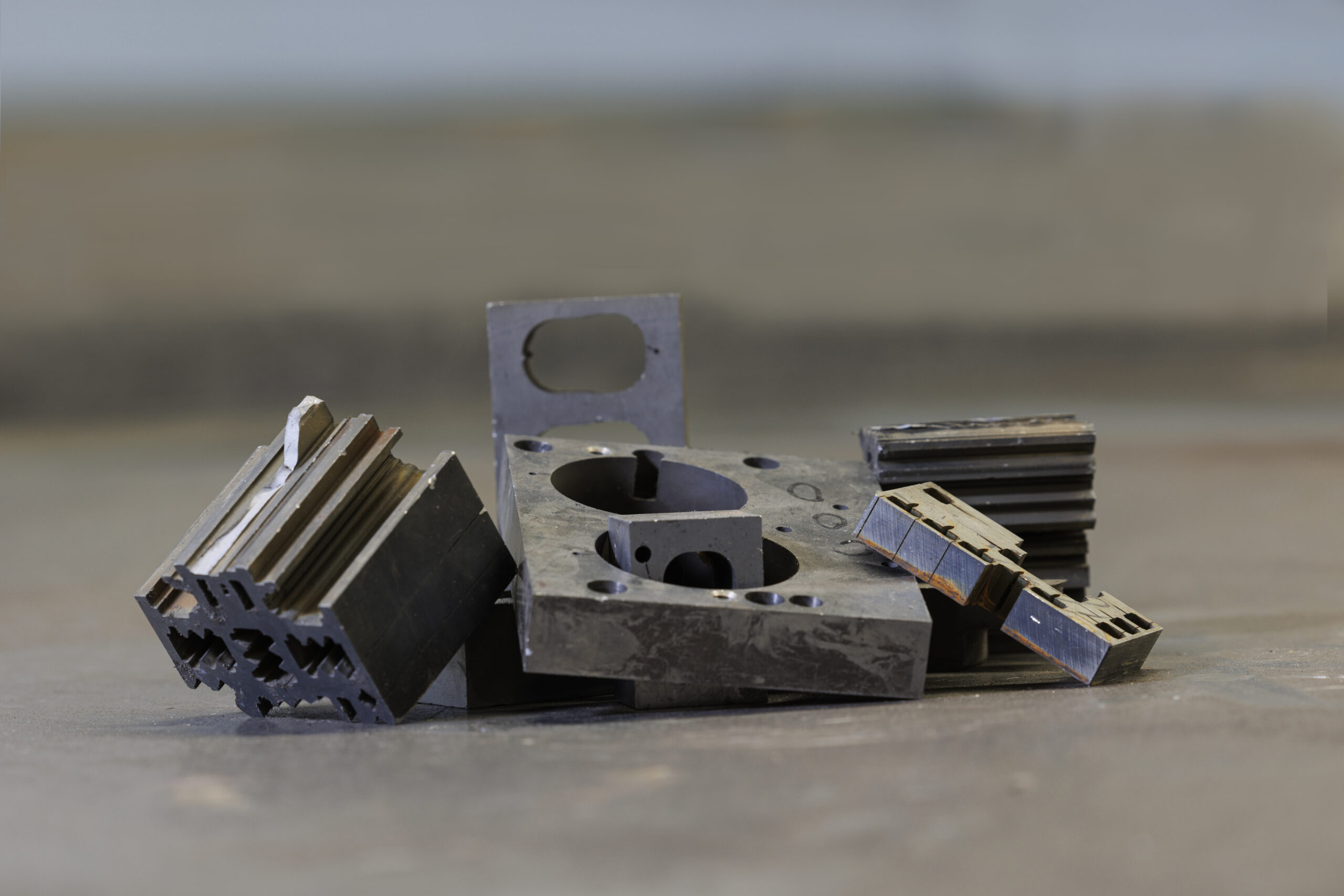

We are able to extract pure tungsten from almost all forms of tungsten scrap and production waste

Mixed Hardmetal

Drills

Inserts

Drill Bits

Morgan Rolls

Moulding Tools

Grinding Sludge

Swarf

The benefits of recycling for our customers and suppliers

Flexible

We can process almost any kind of scrap or production residue containing tungsten. Thanks to our flexible chemical processes, we can also work with mixed scrap packages.

Reliable

We strive for ongoing cooperative relationships in a spirit of mutual trust when it comes to purchasing scrap. This may include arrangements such as longer-term contracts or consignment stock.

Fair

We ensure highly professional, trackable weighing, sampling, and analysis of the scrap samples delivered right here on site. We honor all agreed payment terms.

A true partner

A specialized team works exclusively on purchasing and transporting scrap. These experts are always up to date on relevant topics such as waste disposal law, REACH, hazardous materials classification, and similar. We are happy to help suppliers handle the entire process, from declaration and customs clearance through to billing.

Sustainable

Sustainability is important to us at every level – from operating our facilities with minimum impact on resources to the health of our employees. We have been recycling scrap to use as raw materials in our own production operations for decades. This is a key way we help to protect and conserve the natural environment and reduce harmful emissions.

Responsible

We earned Responsible Smelter certification in 2015 and will fulfill all of the requirements arising from the German Supply Chain Act by 2023. We already meet all of the specifications laid down in the EU regulations (Regulation (EU) 2017/821) on supply chain due diligence. For further information, including certifications and reports, please click here.

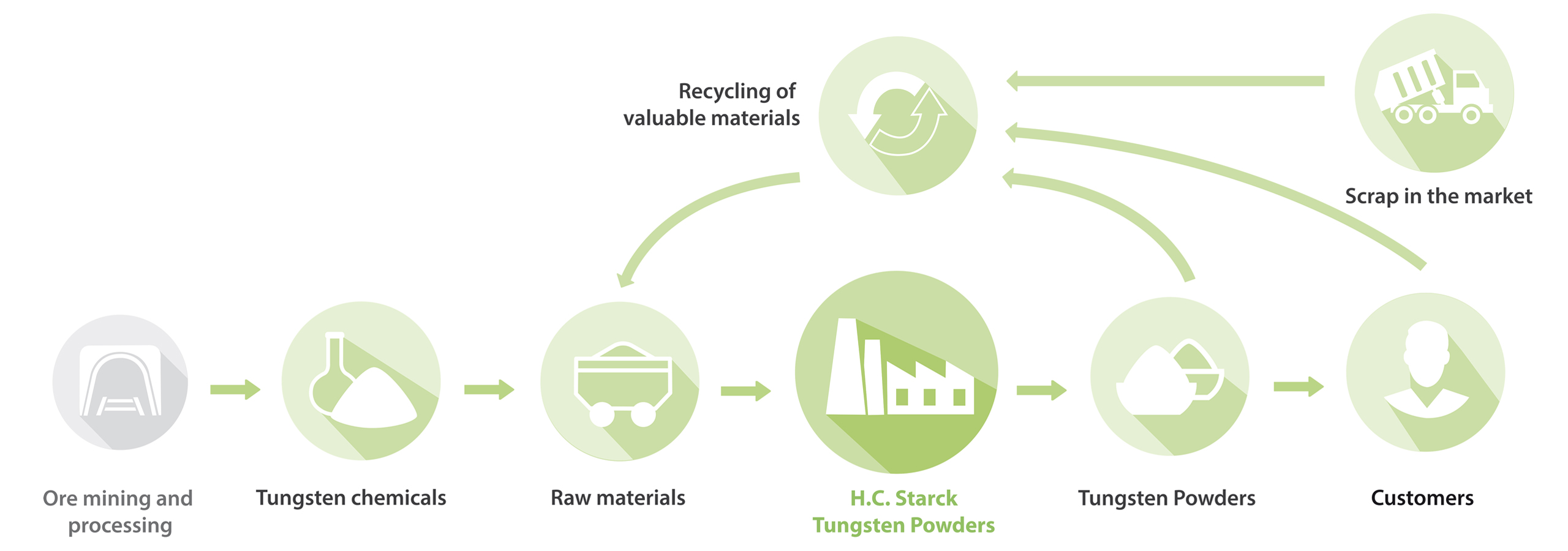

Closed Loop

Get to know our closed-loop production cycle. We can produce pure tungsten from almost any secondary raw material containing tungsten.

We have three processes geared toward returning used materials to the value creation cycle: purchasing scrap that contains tungsten on the market, engaging in reworking business with our customers, and recycling our own production residue.

This is supplemented by the primary raw materials side, where we use tungsten chemicals from conflict-free ores.

Your contact for recycling at H.C. Starck Tungsten Powders

Contact us for selling your scrap! Our experienced team in the raw material purchasing department will help you with every concern.

Ines Kreienfeld

Tel: +49 5321 751 53869

Tanja Stalke

Tel: +49 5321 751 53717

William Parry-Jones

Tel: +84 901 753255